Turning and milling Tools are two of the most important processes in modern manufacturing. Whether you’re making a precision part for a delicate instrument or producing large industrial components, the right tools can make all the difference.

Type of Turning Tools?

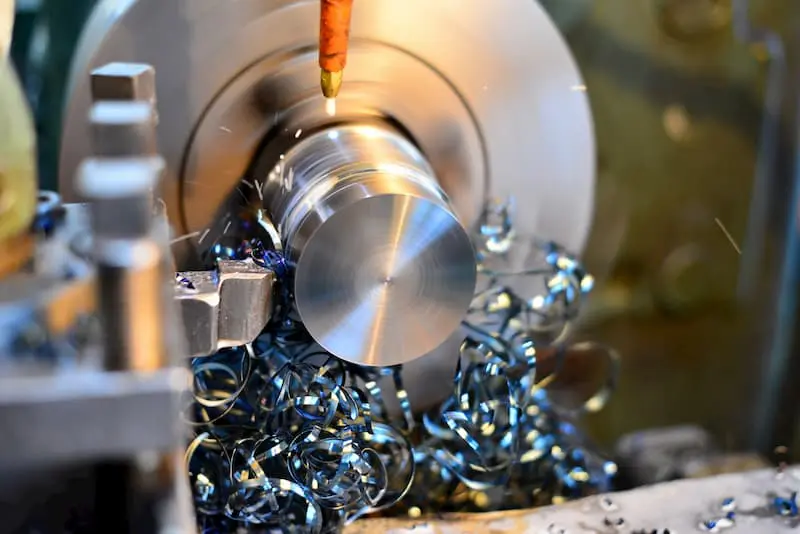

Lathe Tools

Lathe tools are used to cut and shape materials like wood and metal. They include tools for roughing, finishing, and threading.

Ceramics Inserts

Chisels are hand-held tools used to remove material from a workpiece. They come in a variety of shapes and sizes, and are essential for precision work.

Carbide Insert Tools

Carbide insert tools are specialized cutting tools used for high-speed machining. They are made from tough materials that can withstand extreme heat and pressure.

Type of Milling Tools?

End Mills

End mills are used to cut materials with a milling machine. They have cutting edges on both the bottom and the sides, and can be used to create a wide variety of shapes and contours.

Face Mills

Face mills are used to create flat surfaces on a workpiece. They have a large cutting surface that can remove material quickly and efficiently.

Ball Mills

Ball mills are used for grinding materials down to a fine powder. They work by tumbling the material in a rotating cylinder, and can be used for both dry and wet grinding.

Materials Used in Turning and Milling Tools

Steels

Steels are a common material for turning and milling tools because they are strong, durable, and can be sharpened easily. Examples include HSS and carbide.

Ceramics

Ceramics are increasingly being used in turning and milling tools because of their high heat resistance and hardness. They are especially useful for cutting hard materials like titanium and stainless steel.

Diamonds

Diamonds are the hardest material known to man, and are used in turning and milling tools for ultra-precise cuts. They are often used for making fine jewelry and cutting glass.

Factors to Consider When Choosing Turning and Milling Tools

Cutting Speed

The cutting speed of a tool affects the quality of the cut, the tool life, and the surface finish. It’s important to choose a tool that can handle the required speed.

Tool Life

The tool life is how long a tool can be used before it needs to be replaced. It’s important to choose a tool that can last long enough to complete the job.

Surface Finish

The surface finish is the quality of the cut surface. It’s important to choose a tool that can produce the desired surface finish for the job.

Maintenance and Care for Turning and Milling Tools

Keep clean and dry

Wipe down tools after use and store in a dry place to prevent rust and corrosion.

Sharpen regularly

Sharpen tools on a regular basis to ensure optimal performance.

Replace worn tools

Replace worn tools to prevent damage to the workpiece and to maintain accuracy.

Top Suppliers for Turning and Milling Tools

Machenzzo India

Machenzzo is a leading Suppliers of cutting tools for the metalworking industry. They offer a wide range of products, from drills and end mills to indexable inserts and toolholders.

Iscar

Iscar is a global supplier of precision carbide metalworking tools. Their products are used in a variety of industries, including automotive, aerospace, and medical.

Kennametal

Kennametal is a leading supplier of cutting tool solutions. Their products are used in everything from oil and gas exploration to aerospace and defense.

Where to Buy Turning and Milling Tools

Local Tool Stores

Local tool stores like Ace Hardware or Harbor Freight carry a wide selection of turning and milling tools.

Online Retailers

Online retailers like Amazon and Grainger carry an extensive assortment of cutting tools, making it easy to find exactly the tool needed.

Machenzzo Website

Turning and milling tools are also available directly from Website machenzzo.com, often with discounts for bulk orders.