If you are considering investing in a biomass briquetting press, choosing the right equipment to match your production needs is crucial. This guide covers key factors to help select an ideal biomass briquetting press for your operation.

Determine Your Production Requirements

First, analyze your requirements:

- What quantity of briquettes must the biomass briquetting press produce hourly or daily?

- What types and quantities of biomass waste do you intend to compact using the briquetting press?

- What are the properties of your biomass materials – density, moisture content, particle sizes?

- What are your target specifications for the biomass briquettes from the press – size, shape, calorific value?

- Will you need small briquettes for domestic fuel or larger ones for industrial clients?

Your production goals will indicate the capacity of biomass briquetting press needed. Larger capacities are required for higher volumes.

Compare Press Types for Biomass Briquetting

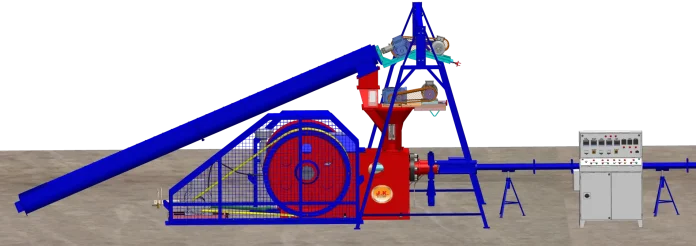

Major biomass briquetting press types include:

- Piston Press: Uses a motorized piston in a cylinder to generate high pressure and compact material into briquettes. Capacities range from 100 kg/hr to 3000 kg/hr. Well-suited for medium output needs.

- Screw Press: Compacts biomass between a rotating screw and sleeve to produce briquettes continuously. Throughputs between 500-2000 kg/hr.

- Hydraulic Press: Generates very high pressure through a hydraulic ram/cylinder system to create dense briquettes. Lower throughput capacities.

- Roller Press: Uses counter rotating rollers with dies to make briquettes at high speeds above 4000 kg/hr. Density of briquettes is lower.

Evaluate each biomass briquetting press type based on your material, production scale and desired briquette characteristics.

Analyze Costs of Biomass Briquetting

The biomass briquetting press purchase price is only one cost aspect. Also consider:

- Operating costs – electricity, maintenance, labor etc.

- Cost of press dies, spare parts, and consumables.

- Any biomass raw material pre-processing needed before briquetting.

- Biomass drying costs if feedstock requires drying.

- Projected revenue from selling the biomass briquettes.

Do break-even analysis and ROI projections to determine economic feasibility.

Choose a Reliable Briquetting Press Manufacturer

The reliability and experience of the biomass briquetting press manufacturer is very important. Seek suppliers who:

- Have 10+ years industry experience with proven performance history

- Use in-house engineering and manufacturing rather than just assembly

- Can provide customized biomass briquetting solutions for your application

- Offer strong technical support and spare parts supply

- Provide training on proper operation and maintenance of the briquetting press

Leading manufacturers like CF Nielsen, Ruf GmbH, WEIMA, JK Bioenergy offer complete biomass briquetting systems.

Conduct Briquetting Trials Before Buying a Press

Extensive briquetting trials are highly recommended prior to purchasing a biomass briquetting press:

- Source all the types of biomass raw materials you intend to use.

- Use rented or pilot scale briquetting equipment to produce test briquettes.

- Vary parameters like pressure, dwell time, material ratios, moisture etc.

- Analyze density, durability, combustion properties of the briquettes.

- Confirm the briquettes meet quality standards and customer requirements.

Repeat the trials until you determine the optimal briquetting parameters for each raw material type.

Plan Support Infrastructure Around the Briquetting Press

Besides the main briquetting unit, additional equipment is required:

- Size reduction equipment if biomass requires shredding before compaction.

- Conveying and dosing systems for material handling to and from the press.

- Drying equipment if the biomass has high moisture content.

- Briquette cooling equipment and storage silos.

- Effluent treatment if generating wastewater.

- Safety features like emergency stops and ventilation.

Take an integrated view of material flows and infrastructure during planning.

In Summary

Choosing the ideal biomass briquetting machine requires thorough assessment of key factors – required output, waste type, briquette properties, costs, and manufacturer reliability. Conducting briquetting trials is highly advisable. With the right press matched to your needs, converting biomass waste into fuel briquettes can become a profitable waste management solution. Consult briquetting experts for further guidance on selecting equipment.