The Banarasi silk saree has a long history, and the word Banarasi comes from Varanasi, also known as Banaras, an important city in India. Banarasi sarees are produced in Varanasi, also known as Banaras, a historic city. This region is known for its luxurious needlework, beautiful silk, and brocade or zari that is made of gold and silver. Due to their fine weave and elaborate motifs, the silk sarees are somewhat weighty as a result of their exquisite engravings.

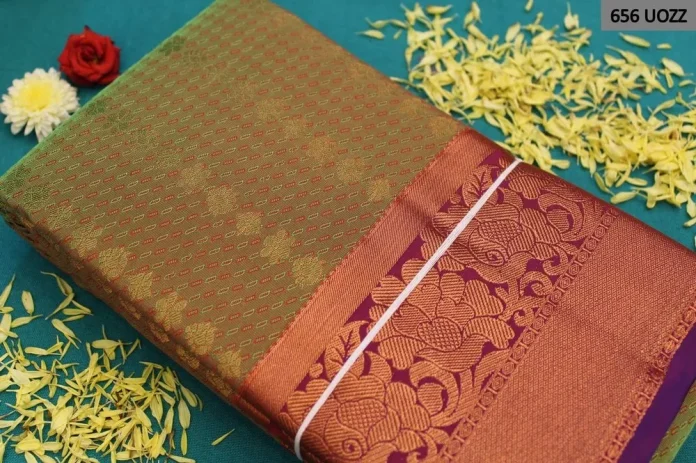

These sarees are distinguished by their intricate interwoven floral and foliate designs, kalga and bel, and a string of erect leaves known as Jhallar at the outer edge of the border.

Gold work, compact weaving, minute details, metallic visual effects, pallus, jal (a pattern resembling a net), and mina work are also included in the art, along with figures with these other elements.

A saree can take anything from 15 days to a month, and perhaps even up to six months, to finish, depending on how intricate the motifs and patterns are. Indian ladies typically wear banarasi sarees to formal events like weddings, when the woman is expected to accessorise with her most expensive jewellery.

The Banarasi Saree’s history

Ralph Fitch (1583–91) said that Banaras’ cotton textile business was booming. The 19th century is when Banaras’ brocades and Zari fabrics were first mentioned. Due to the influx of Gujarati silk weavers during the 1603 famine, silk brocade weaving most likely started in Banaras in the seventeenth century. It’s possible that throughout the 18th and 19th centuries, this reached its pinnacle. During the Mughal Empire, brocades with elaborate patterns were woven in Banaras using gold and silver threads.

About 1.2 million individuals employed directly or indirectly in the handloom silk industry of the region around Varanasi produce the traditional Banarasi saree in a cottage economy.Ekaya, Tilfi Banaras, and HKV Benaras are just a handful of the independent, Varanasi-based firms that have developed in recent years to bring the Banarasi saree back to life and into the hands of popular customers.

An indicator of the Banarasi Saree’s location

Due to competition from mechanised plants that produce Varanasi silk sarees more quickly and a less expensive synthetic alternative to silk, the Banarasi silk handloom sector has been suffering enormous losses over the years.

Weaver groups in Uttar Pradesh finally received Geographical Indication (GI) rights for “Banaras Brocades and Sarees” in 2009, after two years of waiting. A geographical indication (GI) is an intellectual property right that designates a certain area as the source of an item. This is due to the fact that a product’s quality, reputation, or another attribute may mostly be attributed to its place of origin.

Four categories—silk brocades, textile items, silk sarees online, garment materials, and silk embroidery—are used in GI certifications to categorise Banarasi products (23-26). The most crucial part of this is that no saree or brocade may be marketed legally as a Banaras saree or brocade outside of the six districts. Some of the biggest towns in Uttar Pradesh include Varanasi, Mirzapur, Chandauli, Bhadohi, Jaunpur, and Azamgarh.

Nine organisations, including Banaras BunkarSamiti, Human Welfare Association (HWA), director of handlooms and textiles Uttar Pradesh Handloom Fabrics Marketing SahkariSamiti, had submitted applications to the Geographical Indication Registry of the Indian government, which is based in

Various designs of Banarasi saree

Pure silk (Katan), organza (Kora) with silk and zari, Georgette, and Shattir are the four basic types of Banarasi sarees. In terms of the design method, they may be divided into categories like Jangla, Tanchoi, Vaskat, Cutwork, Tissue, and Butidar.

Environment-related issue

Natural colours are now more widely employed as a result of the Ganges River being polluted by chemical dyes from the industry’s numerous silk dying facilities. The process of solvent extraction and enzymatic extraction was utilised by a research team from the Indian Institute of Technology, Banaras Hindu University (IIT-BHU) to create natural colours from plants, flowers, and fruits such acacia, butea (Palash), madder, marigold, and pomegranate (anar).

Traditional Saree weavers are under danger.

It has become more challenging for the weavers to complete the sarees quickly; as a result, their wages are impacted. This is due to the increasingly inconsistent and erroneous electric power supply, which causes the electric-powered looms to sit idle for longer periods of time during the day. Lookalike Banarasi sarees shopping have also overrun the market. These sarees are sold at low costs because they are mass-produced in China on enormous looms.

Conclusion

The ideal pick for a special event is a banarasi saree. It’s a lovely way to display your taste and flair with its detailed, vibrant patterns. A banarasi saree is a wonderful option whether you’re dressed up for a formal event or simply searching for something special to wear.