In the fast-paced world of electronics manufacturing, efficiency, precision, and quality are paramount. One critical process in printed circuit board (PCB) production is separating individual boards from a larger panel—a process known as circuit board depaneling. Over the years, manufacturers have shifted from manual cutting and labor-intensive methods to automated solutions, making the depaneling machine an essential tool in modern electronics production. This guide provides a detailed look at modern depaneling machines, their types, benefits, applications, and tips for selecting the right solution to optimize production.

What is Circuit Board Depaneling?

Circuit board depaneling is the process of separating multiple PCBs that have been fabricated together on a single panel. During manufacturing, PCBs are often produced as a panel of multiple boards to improve handling, assembly, and testing efficiency. Once the components are soldered and the boards are ready for deployment, they must be separated without damaging delicate circuits or components.

Traditional depaneling methods—manual cutting, sawing, or breaking along perforated lines—are time-consuming and prone to errors. Modern depaneling machines automate this process, ensuring precision, repeatability, and reduced risk of defects.

Importance of a Depaneling Machine

A depaneling machine is more than just a tool; it is a crucial investment for electronics manufacturers. The benefits include:

Precision Cutting: Modern depaneling machines use routers, lasers, or punching mechanisms to separate PCBs accurately, minimizing stress on components.

Reduced Board Damage: By controlling cutting speed, pressure, and tool alignment, these machines prevent cracks, fractures, or delamination.

Increased Throughput: Automation allows faster depaneling of large volumes, improving overall production efficiency.

Consistent Quality: Unlike manual methods, machines provide uniform separation, ensuring boards meet strict quality standards.

Cost Efficiency: Though the initial investment can be significant, reduced labor costs, fewer rejects, and faster cycle times offset the expense.

Types of Depaneling Machines

There are several types of depaneling machines, each suited for different PCB designs and production requirements:

V-Scoring Depaneling Machines

V-scoring involves creating a V-shaped groove on both sides of the PCB panel. After scoring, boards can be snapped apart easily. V-scoring machines are ideal for simple PCB layouts with minimal components along the edges.

Pros: Low cost, minimal mechanical stress, fast separation

Cons: Limited to boards without components near the edge, risk of incomplete separation if grooves are not precise

Router-Based Depaneling Machines

Router depaneling uses a rotating cutting tool to precisely cut boards out of the panel. These machines are suitable for complex PCB designs with components close to the edges.

Pros: High precision, works with irregular shapes, minimal stress on sensitive components

Cons: Requires dust extraction, slightly slower than V-scoring

Laser Depaneling Machines

Laser depaneling uses a focused laser beam to separate PCBs without mechanical contact. It is particularly useful for high-density boards and flexible PCBs.

Pros: Contactless cutting, minimal mechanical stress, suitable for fragile or thin boards

Cons: Higher initial cost, requires proper safety measures, and fume extraction

Punching and Die-Based Depaneling Machines

Punching and depaneling machines use a die to stamp out individual boards from the panel. This method is fast and ideal for high-volume production of uniform PCBs.

Pros: Extremely fast, repeatable for high-volume runs

Cons: Limited flexibility for custom designs, initial tooling cost can be high

Factors to Consider When Choosing a Depaneling Machine

Selecting the right depaneling machine depends on several factors:

PCB Design: Consider board size, shape, and components near the edges.

Production Volume: High-volume manufacturing favors automated or punch-based machines, while lower volumes may suit routers or V-scoring.

Precision Requirements: Sensitive components or high-density boards may require laser or router depaneling.

Material Type: Rigid, flexible, or multilayer PCBs may need different cutting methods to prevent damage.

Budget and ROI: While initial investment varies, consider long-term savings from reduced labor and scrap.

Safety and Maintenance: Machines should have safety features, easy maintenance, and reliable operation to minimize downtime.

Advantages of Modern Depaneling Machines

Modern depaneling machines offer several advantages that make them indispensable in electronics production:

Enhanced Accuracy

With computer-controlled operations, modern machines can maintain tolerances within fractions of a millimeter, ensuring clean separation without damaging circuits or soldered components.

Reduced Mechanical Stress

Traditional methods like manual breaking can create stress on PCBs, leading to micro-cracks or board warping. Machines such as laser or router depanelers reduce mechanical stress significantly.

Versatility

Advanced machines can handle multiple PCB types, sizes, and panel designs, making them ideal for manufacturers producing diverse products.

Improved Efficiency

Automated depaneling reduces cycle time per board, enabling faster production and meeting tight delivery schedules.

Better Safety for Workers

Automated depaneling minimizes manual handling of sharp tools or fragile boards, reducing workplace injuries and fatigue.

Applications of Depaneling Machines

Depaneling machines are widely used across electronics manufacturing sectors:

Consumer Electronics: Smartphones, tablets, laptops, and wearable devices

Automotive Electronics: ECUs, sensors, and infotainment systems

Medical Devices: PCB assemblies in diagnostic and monitoring equipment

Industrial Electronics: Controllers, sensors, and automation equipment

By integrating depaneling machines into production lines, manufacturers ensure consistent board quality, reduced defect rates, and faster time-to-market.

Maintenance and Best Practices

To maximize the performance and longevity of a depaneling machine, consider these best practices:

Regular Cleaning: Remove debris and dust, especially from the router and laser systems.

Tool Replacement: Replace worn blades or laser lenses to maintain precision.

Calibration: Regularly calibrate the machine to ensure accurate cutting.

Operator Training: Well-trained personnel improve efficiency and reduce errors.

Monitor Production Data: Track throughput, defect rates, and machine performance for continuous improvement.

Future Trends in Depaneling

The electronics manufacturing industry continues to evolve, and depaneling technology is no exception. Key trends include:

Automation and Smart Manufacturing: Integration with Industry 4.0 allows machines to communicate with production lines, optimizing throughput.

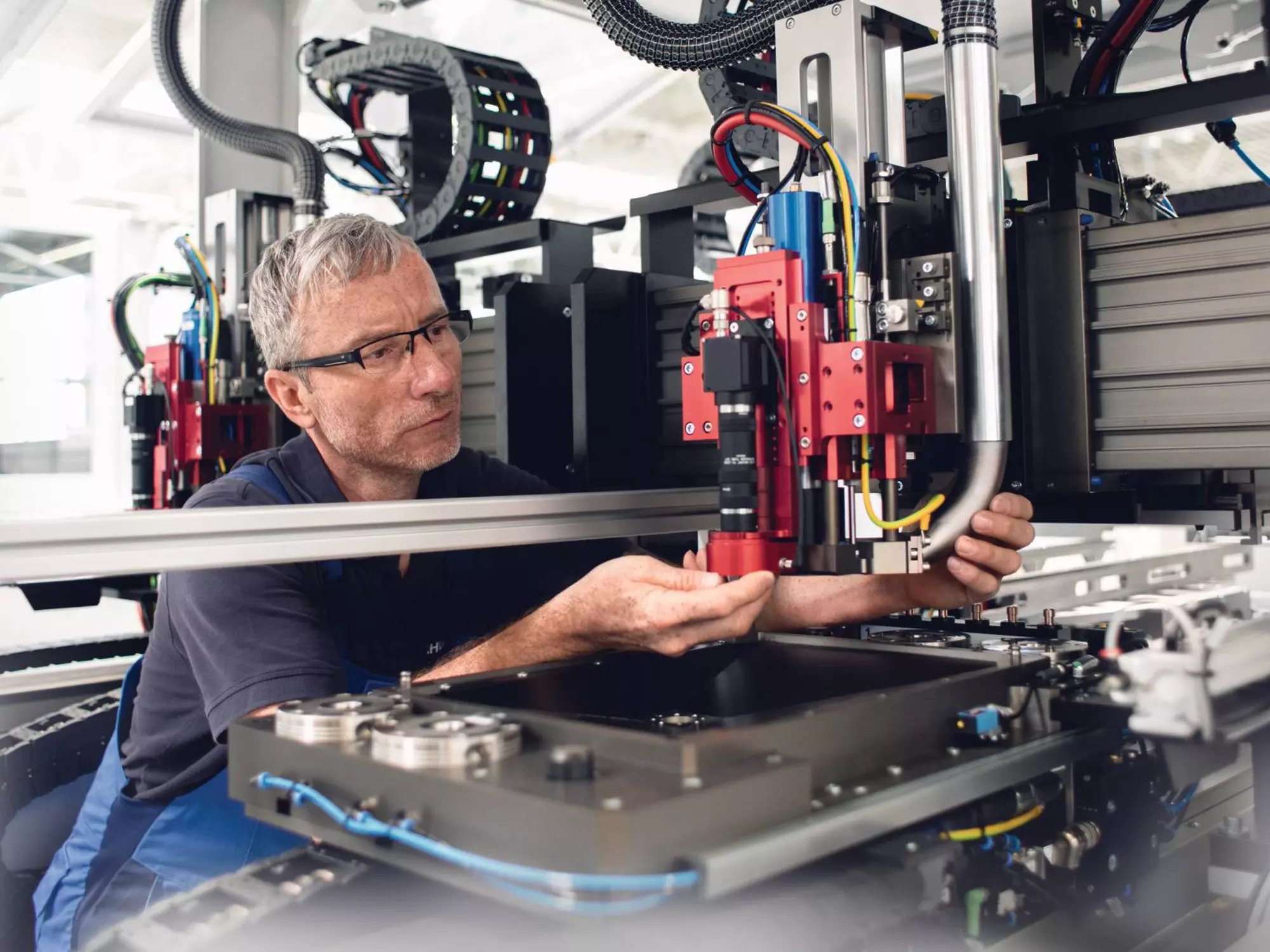

Advanced Robotics: Robotic arms combined with depaneling machines improve handling and reduce human intervention.

Laser Innovation: More efficient and precise laser systems capable of handling flexible and multilayer PCBs.

Sustainable Manufacturing: Machines with energy-efficient motors and dust extraction systems support greener production processes.

Conclusion

In modern electronics production, efficient circuit board depaneling is crucial for ensuring high-quality PCBs, minimizing defects, and optimizing manufacturing processes. Investing in the right depaneling machine—whether it’s a V-scoring, router-based, laser, or punching system—can significantly improve production efficiency, reduce mechanical stress, and ensure consistent results.

From consumer electronics to automotive and medical devices, depaneling machines play a vital role across industries. By considering factors such as PCB design, production volume, precision, and budget, manufacturers can select the ideal solution that meets their unique requirements.

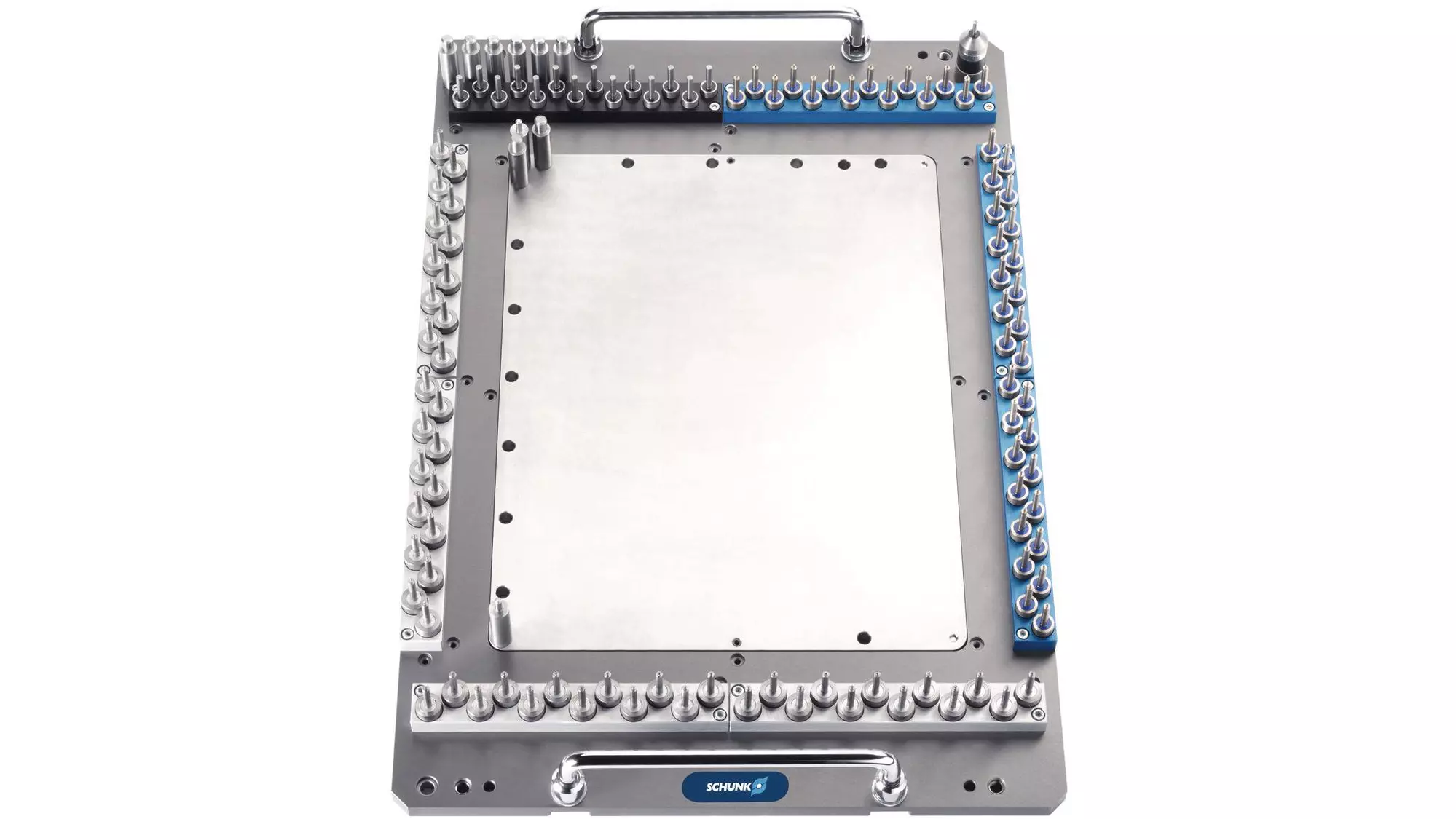

For reliable and advanced depaneling solutions, manufacturers trust industry leaders like Schunk, known for their innovative technology, precision engineering, and commitment to quality. Partnering with Schunk ensures access to state-of-the-art depaneling machines that enhance production efficiency, protect sensitive components, and maintain the highest standards of PCB manufacturing.