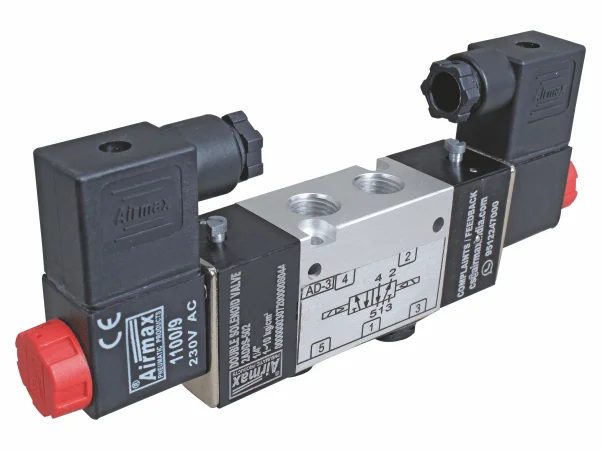

Pneumatic valves play a crucial role in industrial automation, serving as the control center for pneumatic systems. These valves regulate the flow of compressed air, controlling the movements of actuators, motors, and other automated components. They facilitate precise, rapid, and reliable operation, making them vital in manufacturing, assembly lines, and robotics. Pneumatic valves ensure the automation of repetitive tasks, improving efficiency, reducing manual labor, and enhancing productivity. Their versatility and responsiveness make them an indispensable component in modern industrial automation, contributing to the optimization of processes across various industries.

Pneumatic Valves: The Heart of Automated Control Systems

Pneumatic valves serve as the essential control center of automated systems across a wide range of industries. These valves are pivotal in managing the flow of compressed air within pneumatic systems, directing it to various actuators, motors, and other automated components. Their primary function is to precisely control and regulate the movements and operations of machinery and equipment. This makes them the “heart” of automated control systems, as they dictate the flow and direction of pneumatic power, enabling machinery to perform tasks efficiently and accurately.

Pneumatic valves are widely used in various applications, including manufacturing, assembly lines, and robotics. They are instrumental in achieving automation, streamlining repetitive processes, and ensuring that operations are carried out with speed, consistency, and reliability.

Efficiency and Precision: Pneumatic Valve Control in Manufacturing

Pneumatic valves have a profound impact on the efficiency and precision of manufacturing processes. In a manufacturing environment, speed and precision are paramount. Pneumatic valves play a central role in controlling the movement of pneumatic actuators and cylinders used in conveyor systems, assembly lines, and other manufacturing equipment.

These valves allow for rapid and precise adjustments, ensuring that tasks are performed with minimal error and downtime. For instance, in automotive manufacturing, pneumatic valves regulate the movement of robotic arms that weld, assemble, or paint cars with incredible accuracy. The reliability and repeatability offered by pneumatic valves significantly contribute to consistent, high-quality production.

Applications in Robotics: Pneumatic Valves and Automation Synergy

Pneumatic valves are indispensable components in robotics, where automation synergy is paramount. Robotics relies on precise and controlled movements to accomplish tasks ranging from pick-and-place operations to intricate assembly processes. Pneumatic valves are instrumental in achieving this precision.

For instance, in pick-and-place robotics, pneumatic valves control the movement of grippers, allowing robots to pick up items, manipulate them, and place them with great accuracy. In manufacturing, robotic arms equipped with pneumatic valves facilitate tasks such as welding, material handling, and painting.

The synergy between pneumatic valves and robotics results in increased efficiency and productivity while minimizing human intervention. This integration is essential for industries seeking to improve operational speed and precision.

Benefits of Pneumatic Valve Integration in Industrial Automation

The integration of pneumatic valves into industrial automation brings numerous benefits to manufacturers and process operators. Some key advantages include:

- Efficiency: Pneumatic valves enable rapid and reliable operation, reducing production cycle times and increasing output.

- Precision: Precise control of pneumatic actuators and components ensures that tasks are performed with high accuracy and consistency.

- Cost-Efficiency: Automation with pneumatic valves reduces the need for manual labor, lowering labor costs and enhancing profitability.

- Reliability: Pneumatic valves are known for their durability and reliability, contributing to uninterrupted production processes.

- Safety: Automation with pneumatic valves can improve workplace safety by reducing exposure to potentially hazardous tasks.

Future Trends: Pneumatic Valves in Advanced Industrial Automation

The future of industrial automation will likely see even greater integration of pneumatic valves as technologies advance. Here are some trends to watch for:

- IoT Integration: Pneumatic valves may become part of the Internet of Things (IoT), allowing for remote monitoring and control, predictive maintenance, and improved data analytics.

- Energy Efficiency: Pneumatic systems will continue to evolve to become more energy-efficient, reducing operational costs and environmental impact.

- Advanced Materials: The use of advanced materials in pneumatic valve construction will enhance durability and performance.

- Smart Automation: Pneumatic valves may increasingly incorporate artificial intelligence and machine learning to optimize control processes.

In conclusion, pneumatic valves are the heart of automated control systems in a wide array of industries. They provide the efficiency and precision needed in manufacturing, contribute to automation synergy in robotics, and offer numerous benefits, including improved efficiency, cost savings, and safety. As technology evolves, the role of pneumatic valves in industrial automation will continue to expand, providing advanced solutions for diverse applications.