Plastic injection molding is a versatile manufacturing process that creates a wide range of plastic products, from consumer goods to automotive components. It offers numerous advantages, including high precision, consistency, and cost-effectiveness for mass production. However, understanding the various cost components associated with plastic injection molding is crucial for businesses looking to optimize their production processes and budgets effectively. This article will delve into the critical aspects of plastic injection molding costs, including injection mold tooling expenses and plastic injection mold costs.

Plastic Injection Molding: An Overview

Plastic injection molding is a manufacturing technique that involves injecting molten plastic material into a custom-designed mold cavity to create a specific shape. This process is widely used because it produces high-quality, uniform parts at scale. When calculating the cost of plastic injection molding, it’s essential to consider several factors:

Injection Mold Tooling Cost

The plastic injection molding cost is a significant upfront investment in plastic injection molding. Tooling refers to creating molds or dies to shape the plastic material into the desired product. This step is essential because the mold’s quality and precision directly impact the final product’s quality.

Several factors influence injection mold tooling costs:

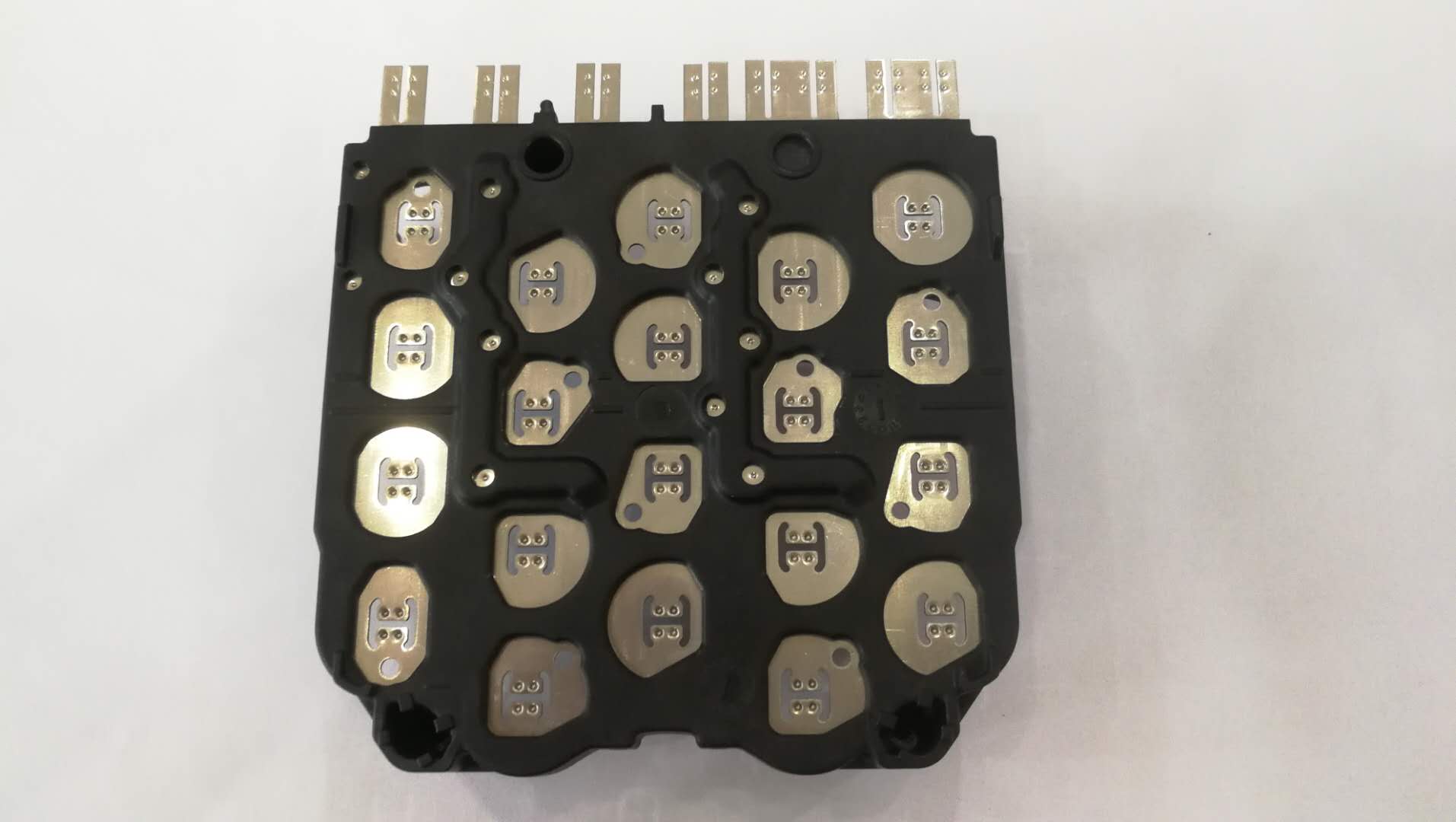

Mold Complexity: The complexity of the mold design has a substantial impact on tooling costs. Simple molds with fewer features and undercuts are cheaper than complex, multi-cavity molds.

Material Selection: The choice of mold material, such as steel or aluminum, affects injeciton mold cost. Steel molds are more durable and costlier upfront but can withstand high-volume production, reducing long-term costs.

Mold Size: Larger molds require more material and machining time, leading to higher tooling costs. Smaller molds are generally more affordable.

Mold Design and Tolerance: Precise and intricate mold designs with tight tolerances demand more time and precision in manufacturing, resulting in higher tooling expenses.

Mold Maintenance: Over time, molds can wear out due to continuous use. Regular maintenance is necessary to extend their lifespan and avoid unexpected repair costs.

Plastic Injection Mold Cost

The injection mold tooling cost encompasses designing, manufacturing, and maintaining the mold. This cost is a critical consideration because it significantly impacts the molded parts’ overall production cost and quality.

Design and Engineering: The initial phase of mold creation involves designing and engineering the mold according to the product specifications. Skilled designers and engineers are crucial in determining the mold’s cost.

Mold Manufacturing: The actual fabrication of the mold involves machining and assembling the mold components. The materials used, such as steel or aluminum, and the intricacy of the design are key factors influencing manufacturing costs.

Mold Maintenance and Repairs: To ensure the mold’s longevity and consistent product quality, regular maintenance and, occasionally, repairs are required. Budgeting for these ongoing expenses is essential.

The injection mold tooling cost encompasses designing, manufacturing, and maintaining the mold.

Injection Mold Cost vs. Production Volume

When assessing plastic injection mold cost, one important consideration is the relationship between mold expenses and production volume. While the upfront investment in mold creation may seem significant, it becomes more cost-effective as production volume increases. High-volume production allows businesses to spread the initial tooling and mold costs over more significant units, reducing the per-unit cost.

Ways to Reduce Plastic Injection Molding Costs

Businesses can take several steps to minimize plastic injection molding costs and improve their overall profitability:

Design Optimization: Collaborate closely with design engineers to create cost-effective product designs for injection molding. Reducing complexity, minimizing undercuts, and eliminating unnecessary features can all help lower tooling and production costs.

Conclusion

Understanding plastic injection molding costs, including injection mold tooling expenses and plastic injection mold costs, is essential for businesses looking to leverage this manufacturing process effectively. While the initial investment in tooling and mold creation can be substantial, the long-term benefits of producing high-quality, consistent parts at scale often outweigh these costs. By carefully considering design optimization, material selection, and efficient production practices, businesses can minimize expenses and enhance their competitiveness in the market. A well-managed approach to plastic injection molding costs can lead to greater profitability and success in the manufacturing industry.